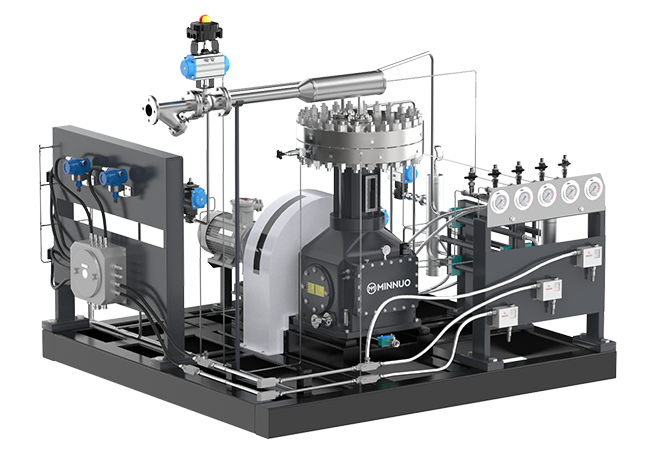

NITROGEN GENERATOR

A nitrogen generator is a device that separates high-purity nitrogen directly from air through physical methods. The mainstream technologies currently include Pressure Swing Adsorption (PSA) and Membrane Separation.

how is a nitrogen generator work ?

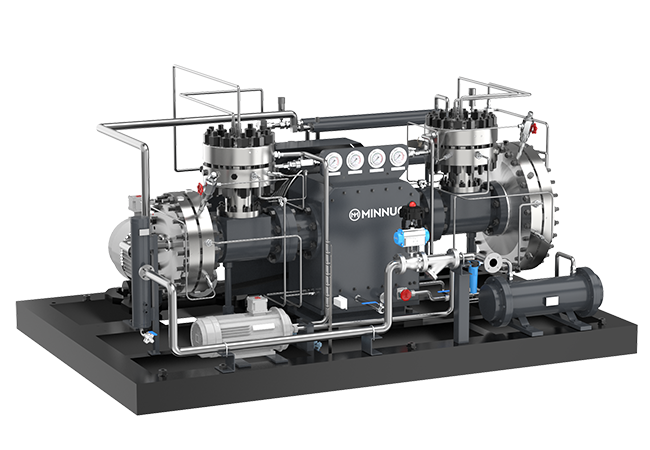

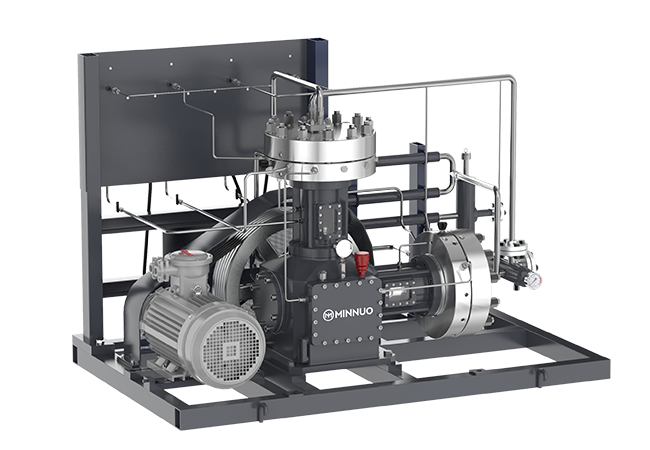

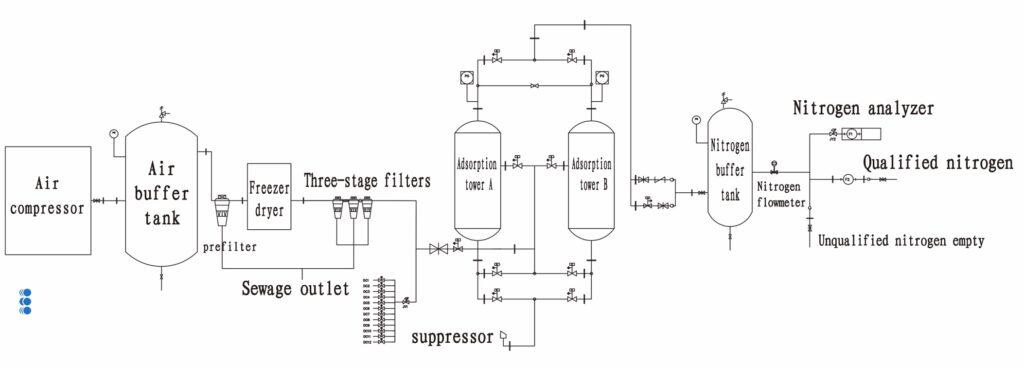

PSA Nitrogen Generator: Utilizes the differential adsorption rates of oxygen and nitrogen on carbon molecular sieves. Through a cyclic process of pressurization (adsorption) and depressurization (desorption), nitrogen is separated from air.

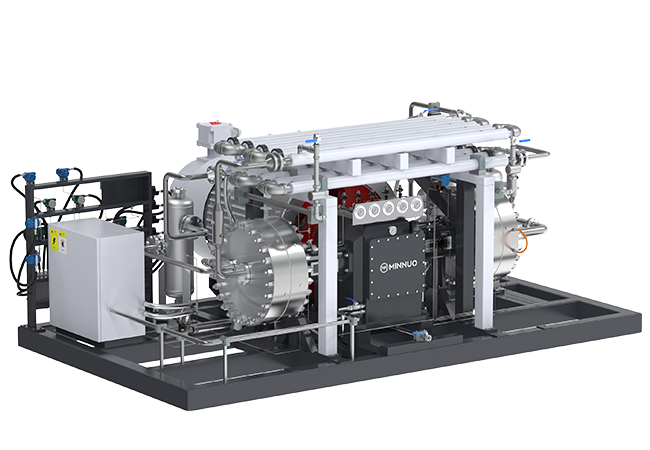

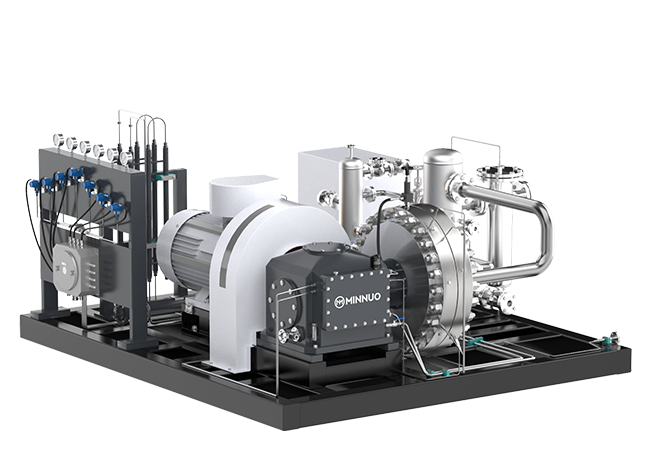

Membrane Separation Nitrogen Generator: Leverages the difference in permeation rates between “fast gases” like oxygen and water vapor and nitrogen (“slow gas”) through hollow-fiber membranes to achieve separation of nitrogen from other gases.

Both technologies enable continuous, automated on-site nitrogen generation, replacing traditional liquid nitrogen and nitrogen cylinders.

Wide-Ranging Applications of Nitrogen Generators

Nitrogen generators provide safe and economical solutions for processes requiring an inert protective atmosphere, with extensive applications in:

- Electronics Industry: Used in SMT assembly, reflow and wave soldering of semiconductor components to prevent oxidation.

- Food & Pharmaceuticals: Applied in modified atmosphere packaging (MAP) of grains, fruits, snacks, and medicinal storage, effectively inhibiting microbial growth and extending shelf life.

- Chemicals & Petroleum: Served as protective, sealing, and purging gas in chemical production, along with tank inerting for safety assurance.

- Metal Heat Treatment: Providing protective atmospheres during quenching, tempering, and annealing to prevent surface oxidation and enhance product quality.

- Rubber & Plastics: Preventing oxidative aging during high-temperature molding of tires and plastic products, improving performance.

Core Advantages of Jufeng Nitrogen Generators

- Significant Cost Efficiency: Only requires electricity and compressed air for operation, resulting in extremely low running costs. Compared to purchasing liquid nitrogen or gas cylinders, it can reduce gas costs by 30% - 70%, with a short investment payback period. Years of molecular sieve installation experience ensure proper initial setup—no loosening or leakage—guaranteeing long sieve life. Intelligent controls enable the system to operate based on actual nitrogen demand, producing only what is needed to prevent waste. The unit automatically shuts down or restarts during low-demand periods, minimizing operational costs and saving substantial electricity.

- Stable & Safe Supply: Enables 24/7 uninterrupted nitrogen supply, eliminating risks associated with liquid nitrogen supply instability, transportation delays, and cylinder handling, ensuring production continuity. Equipped with a purity analyzer, pressure gauge, and flow meter, the system displays nitrogen purity, pressure, and flow rate in real time, with automatic alarms if purity falls below the set limit.

- High Purity & On-Demand Adjustment: Flexibly adjusts and stably produces nitrogen with purity levels ranging from 95% to 99.999% according to specific process requirements, avoiding purity waste.

- Easy Operation & On-Site Production: Fully automatic operation with one-touch start/stop, simple to use. Nitrogen is generated and used immediately on-site, requiring no storage, functioning as a truly independent "self-owned gas source". Automated valve control allows unmanned operation; the system reaches normal gas supply within 15 minutes of startup and can be activated on demand.

Project Case Study

FAQ

Q1: How to choose between a PSA Nitrogen Generator and a Membrane Separation Nitrogen Generator?

A1:

The choice primarily depends on your purity requirements.

PSA Nitrogen Generation: Offers a wide purity range (95% – 99.999%), high flow capacity, and excellent stability, making it the preferred choice for most industrial applications.

Membrane Separation Nitrogen Generation: Typically provides purity below 99.5%. It features a simpler structure and greater mobility, suitable for applications with lower purity requirements, such as oil and gas pipeline protection.

Q2: What are the requirements for the intake compressed air for a Nitrogen Generator?

A2:

The requirements are extremely stringent. It requires clean, dry, and oil-free compressed air. A pre-treatment system with a refrigerated dryer (or adsorption dryer) and multi-stage precision filters is essential. Otherwise, oil and moisture can quickly damage the carbon molecular sieve or membrane module, leading to equipment failure.

Q3: Is a higher nitrogen purity always better?

A3:

Not necessarily. The guiding principle is to “meet process requirements with a slight margin.” Excessively high purity demands significantly increase equipment investment and operating costs. Select the most economical and suitable purity level based on your specific application.

Q4: Is equipment maintenance complex?

A4:

Routine maintenance is simple. The primary task is regular replacement of the pre-filter elements. Core components (e.g., carbon molecular sieve or membrane module) have a long service life and typically last 5-10 years with adequate pre-treatment protection.