Refrigerated Air Dryer

With over 20 years of expertise in hydrogen compression technology, JUFENG is a leading provider in the world. More than 2,000 of our units are successfully operating in various hydrogen applications, delivering a combined installed horsepower exceeding 2 million.

What is a Refrigerated Air Dryer ?

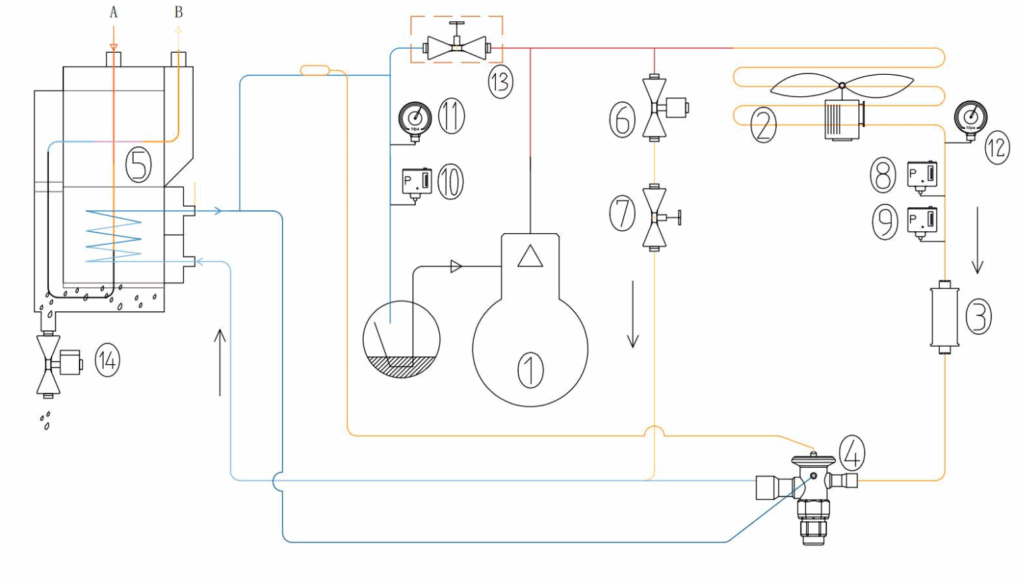

A refrigerated air dryer, the core equipment in a compressed air post-treatment system, operates on the principle of “moisture removal through cooling.”

It utilizes a refrigeration system to cool the warm, saturated compressed air to a lower pressure dew point (typically 2–10°C). This process causes the large amount of water vapor in the air to condense into liquid water, which is then thoroughly removed by an efficient water separator. The final output is clean, dry compressed air, achieved through an efficient and economical physical drying method.

Wide-Ranging Applications of Air Dryers

An air dryer is an essential industrial equipment designed to remove moisture from compressed air, ensuring a clean, dry, and high-quality air supply. By eliminating water vapor, air dryers prevent a multitude of problems caused by moisture, such as corrosion in pipelines, damage to pneumatic tools, and contamination of end products. Their critical role in protecting equipment and ensuring process integrity makes them indispensable across numerous sectors.

The applications of air dryers are vast and varied:

- Manufacturing & Automation: They protect sensitive pneumatic machinery, CNC tools, and robotic actuators from rust and failure, ensuring precision and reducing downtime.

- Food & Beverage Industry: Dry, contaminant-free air is crucial for packaging, mixing, and conveying products. It prevents spoilage and maintains the highest hygiene standards.

- Pharmaceutical & Medical: In these sterile environments, air dryers provide the ultra-dry, oil-free air required for manufacturing drugs, operating medical devices, and packaging.

- Electronics & Semiconductor: Moisture can destroy electronic components during production. Air dryers create a dry environment for assembly and testing.

- Chemical & Petrochemical: They prepare instrument air for control systems and processes where moisture could cause hazardous reactions or inaccurate measurements.

- Transportation: From powering train brakes to sanding systems in commercial vehicles, dry air ensures safety and reliability.

Outstanding Advantages of Refrigerated Air Dryers

Key Advantages

Among various drying technologies, refrigerated air dryers have become the most mainstream choice due to their efficiency, cost-effectiveness, and reliability. Our dryers offer even greater advantages:

- Excellent Energy Efficiency:Utilizing a high-efficiency heat exchange system and optimized core components, our dryer consumes a maximum power of only 9.42 kW even when handling an air flow rate of up to 45 m³/min, resulting in significantly lower operating costs compared to similar products.

- Wide Range of Models:We offer a complete series of models covering flow rates from 1.3 to 45 m³/min, precisely matching the needs of small workshops to medium-sized plants while avoiding resource waste.

- Consistent Drying Performance:Our dryers reliably maintain the pressure dew point of compressed air within a range of 2–10°C, effectively removing the vast majority of liquid moisture and meeting the requirements of most industrial applications.

- Low Maintenance & High Reliability:Featuring a simple and rational structural design with high-quality key components, our dryers support long-term continuous stable operation with minimal maintenance, resulting in a low total cost of ownership. Additionally, we have incorporated an electric defrost valve to ensure stable performance even in low-temperature environments.

- Chemical & Petrochemical: They prepare instrument air for control systems and processes where moisture could cause hazardous reactions or inaccurate measurements.

- Transportation: From powering train brakes to sanding systems in commercial vehicles, dry air ensures safety and reliability.

Project Case Study

FAQ

Q1: Can a refrigerated air dryer completely remove all moisture from compressed air?

A1:

It cannot remove water vapor in its gaseous state. Refrigerated dryers primarily reduce the air temperature to condense and remove liquid moisture, with their drying capacity measured by the “pressure dew point” (typically 2–10°C). If a lower dew point is required (e.g., below -20°C), an adsorption dryer should be selected.

Q2: How do I select a suitable refrigerated dryer for my air compressor?

A2:

The selection is primarily based on two parameters:

The selection is primarily based on two parameters:

The compressor’s rated working pressure (MPa/Bar).

Our professional team can provide complimentary sizing recommendations.

Q3: Is the installation of a refrigerated dryer complicated?

A3:

Not at all. It is typically installed between the air compressor and the air receiver tank. Only inlet/outlet piping connections and a power supply are required. We provide detailed installation guidance.

Q4: What routine maintenance does a refrigerated dryer require?

A4:

Maintenance is very simple. It mainly involves periodically cleaning the condenser to ensure efficient heat dissipation, and regularly inspecting and draining the automatic drain valve to confirm proper operation.