Adsorption Air Dryer

An adsorption air dryer is a purification device that uses adsorbents (such as high-performance molecular sieves or activated alumina) to deeply remove water vapor from compressed air. Its core principle is adsorption under pressure and regeneration through depressurization or heating.

How is an Adsorption Air Dryer work?

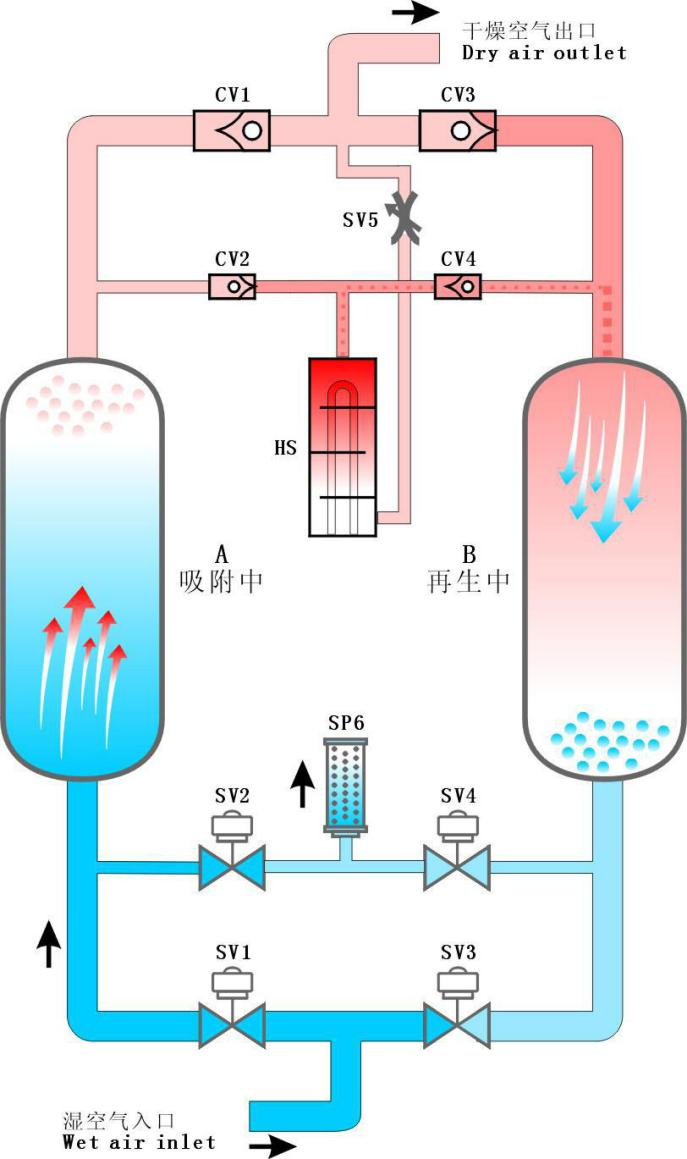

The equipment is typically equipped with two towers filled with adsorbent. While one tower is in operation, moist compressed air flows through the adsorbent, where water molecules are extensively captured, thereby producing dry air with an extremely low dew point. Simultaneously, the other tower regenerates by releasing the adsorbed moisture out of the system through pressure reduction purge or low-temperature heating, restoring the adsorbent’s activity. The two towers alternate cycles to achieve continuous and stable deep drying.

Wide-Ranging Applications of Adsorption Air Dryers

Adsorption dryers are the essential solution for applications requiring low dew points and demanding environmental conditions, with extensive use in:

- Critical Process Gases: Provides deeply dried air for plastic pellet (e.g., PET, PA) drying, powder conveying, and instrument air systems, preventing agglomeration and clogging.

- Extreme Environment Applications: Ensures reliable operation in cold climates by preventing ice formation in compressed air pipelines and end-use equipment.

- High-Tech and Sensitive Industries: Supports semiconductor manufacturing, lithium-ion battery production, aerospace, and medical breathing air applications, where extremely stringent moisture content standards must be met.

- Alternative to Refrigerated Dryers: Serves as the only viable option when a pressure dew point below -20°C is required by the process.

Core Advantages of Adsorption Air Dryers

SV1 Tower A Inlet Valve

SV2 Tower A Regeneration Valve

SV3 Tower B Inlet Valve

SV4 Tower B Regeneration Valve

CV1 Tower A Dry Gas Check Valve

CV3 Tower A Regeneration Gas Check Valve

CV2 Tower B Dry Gas Check Valve

CV4 Tower B Regeneration Gas Check Valve

SV5 Throttle Valve

HS Heater

SP6 Muffler/Silencer

A&B Adsorption Tower

- Deep Drying with Extremely Low Dew Point: Capable of consistently producing ultra-dry air with a pressure dew point as low as -20°C to -70°C, fundamentally eliminating all moisture-related risks.

- Strong Environmental Adaptability: Performance remains unaffected by ambient temperature variations, ensuring stable low dew point output even under extreme conditions, from hot and humid summers to cold winters.

- High Reliability and Durability: Long service life of the core adsorbent, combined with a relatively simple system structure, enables long-term stable operation with low failure rates when properly maintained.

- Modular Design (High-End Models): Jufeng offers modular configurations featuring modular adsorbent cartridges. These systems can be integrated as a complete package with compressors, refrigerated dryers, and air receivers, providing a seamless installation experience without additional effort.

Project Case Study

FAQ

Q1: How do I choose between an adsorption dryer and a refrigerated dryer?

A1:

-

This is a fundamental selection criteria, and the key determining factor is your required pressure dew point.

If your process requires a dew point above 0°C, a refrigerated dryer is the more economical and energy-efficient choice.

If your process requires a dew point below 0°C, especially as low as -20°C or -40°C, an adsorption dryer is essential.

Q2: Why does an adsorption dryer consume compressed air during regeneration?

A2:

In traditional heatless adsorption dryers, a portion of the dried air (approximately 12–15%) is used to purge the saturated tower, stripping absorbed moisture from the adsorbent and expelling it from the system. This is the basic principle of regeneration for this type of dryer.

Q3: Do Jufeng's adsorption dryers offer advantages in compressed air consumption?

A3:

-

Yes. Advanced technologies such as heated purge and blower-assisted heated regeneration significantly reduce the air consumption required for the regeneration cycle. Jufeng’s adsorption dryers are equipped with specialized heaters that can lower the air consumption rate to less than half of traditional models, typically not exceeding 7%.

Q4: Does the adsorbent need replacement? How often?

A4:

-

Yes. Over time, adsorbents lose effectiveness due to oil contamination (poisoning) or mechanical wear. The replacement interval depends on inlet air quality, operating load, and environmental conditions, but it is typically around 1 year. Installing high-efficiency pre-filters can effectively extend the adsorbent’s service life.