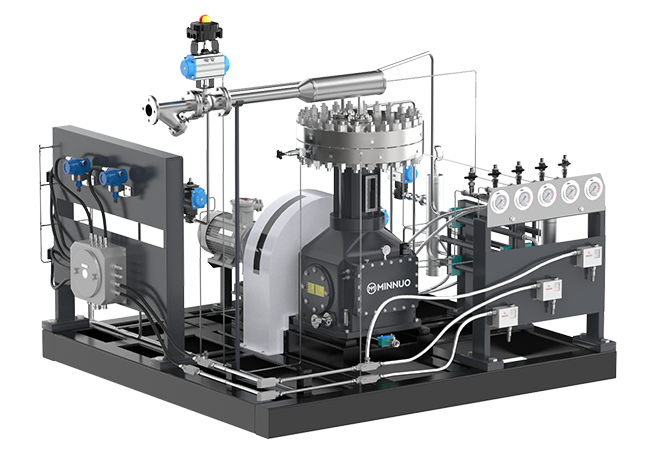

Oxygen Generator

An oxygen generator, professionally referred to as an on-site oxygen generation plant, operates on the core principle of Pressure Swing Adsorption (PSA) technology. It directly separates oxygen from ambient air, providing a safe, economical, and highly efficient method of oxygen production.

How is an Oxygen generator work?

The equipment contains a specialized molecular sieve with a high adsorption affinity for nitrogen in the air. When compressed air passes through the sieve under pressure, nitrogen is adsorbed, allowing oxygen (with a purity of 90%–95% or higher) to be separated and delivered as product gas. Through rapid pressure switching and regeneration cycles between dual towers, the system ensures continuous and stable oxygen production.

Wide-Ranging Applications of Oxygen Generators

On-site oxygen generation technology is progressively replacing traditional liquid oxygen and gas cylinders due to its cost and safety advantages, with extensive applications across:

- Healthcare & Wellness: Provides centralized medical-grade oxygen supply for hospitals, clinics, and nursing homes, serving as a reliable source for ward and clinical use.

- Aquaculture: Enhances dissolved oxygen levels to improve survival and growth rates of fish, shrimp, and other aquatic species, significantly increasing stocking density and operational profitability.

- Industrial Metallurgy & Cutting: Supports metal welding, cutting, glass manufacturing, and oxygen-enriched combustion processes, effectively elevating flame temperature and processing efficiency.

- Wastewater Treatment & Environmental Protection: Introduces oxygen into sewage treatment systems to strongly activate aerobic microorganisms, accelerating pollutant decomposition and improving treatment performance.

- Chemical & Pulp Production: Serves as a feed gas for oxidation processes in chemical production, or utilized in pulp bleaching operations.

Core Advantages of Oxygen Generators

- Significant Cost Reduction: Requires only electricity and air to continuously produce oxygen. Compared to frequent procurement of liquid oxygen or gas cylinders, it can reduce gas costs by up to 50%.

- Safe, Convenient & On-Demand Production: Eliminates safety risks associated with liquid oxygen storage and high-pressure cylinder handling. Enables on-site oxygen generation with no storage needs – immediate production and use ensure a stable supply.

- Intelligent Control & User-Friendly Operation: Fully automated operation with one-touch start/stop. Allows real-time monitoring and adjustment of oxygen purity, flow rate, and pressure, supporting unmanned operation.

- Stable, Reliable & High-Purity Output: Utilizes high-quality molecular sieves and optimized control programs to consistently generate high-purity oxygen at 93% ± 3%, meeting the requirements of most applications.

Project Case Study

FAQ

Q1: Can the oxygen purity of an oxygen generator reach 100%?

A1:

No. Standard oxygen generators utilizing PSA (Pressure Swing Adsorption) technology typically achieve an economical and practical oxygen purity range of 90% to 95%. While higher purity levels (e.g., ~95% to 95%) are possible with more advanced systems like VPSA (Vacuum Pressure Swing Adsorption), attaining 99%+ purity often requires significantly more complex processes, which substantially increases costs. The provided purity range of 90%-95% is already sufficient for most medical, aquaculture, and industrial applications.

Q2: Does the molecular sieve need replacement? How often?

A2:

Yes, the molecular sieve is a core consumable component and requires periodic replacement. However, its service life is considerably long. Under normal operating conditions and with adequate protection (such as by high-efficiency pre-filters ensuring clean intake air), the lifespan of the molecular sieve can typically reach 5 to 8 years or even longer. The replacement interval can be influenced by factors such as inlet air quality and operating load.

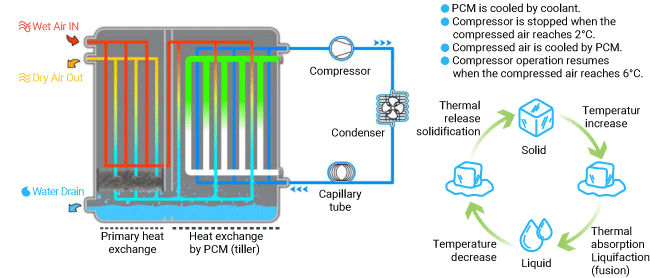

Q3: What are the requirements for the compressed air fed into the oxygen generator?

A3:

Oxygen generators have high requirements for the intake compressed air. The air must be clean, dry, and oil-free. It is essential to equip refrigerated dryers (or adsorption dryers) and precision filters as pre-treatment equipment. Without these, moisture and oil vapors can quickly poison the molecular sieve, leading to a permanent loss of its adsorption capacity and ultimately system failure.

Q4: What is the return on investment (ROI) of an oxygen generator compared to liquid oxygen or gas cylinders?

A4:

While the initial equipment investment for an on-site oxygen generator is higher than simply purchasing gas cylinders, the long-term economic benefits are substantial. For scenarios with continuous or high-volume oxygen demand, the significant savings on gas costs often allow the equipment to pay for itself within a typical payback period of 1 to 3 years. Following this period, users benefit from ongoing cost reduction and enhanced operational efficiency. This makes on-site generation a cost-effective and reliable alternative to depending on external suppliers of liquid oxygen or gas cylinders.